From the cotton gin to the assembly line, innovations in manufacturing have made it easier for entrepreneurs to grow their businesses without hiring extra employees. A more modern example of this, the 3d printer, has made it so that anyone can start a small business almost immediately that would be capable of manufacturing parts from computer files that would make rapid prototyping easier than ever. With the influence of 3d printing reaching into medicinal, food, and industrial production fields, owning or knowing how to use a 3d printer has become incredibly valuable within certain fields. With the growing popularity of small businesses, 3d printing has become as essential as items such as a cash register in some businesses, allowing owners to test new ideas for products without the need for purchasing high-quality test products. Being such an important piece of technology in the growth of manufacturing, it’s important to know where 3d printing started.

Despite seeming like a relatively new piece of technology, 3d printing has its origins in 1981 by a man named Hideo Kodama, from Japan. Kodama used a UV-reactive resin, known as a photopolymer, to create the first-use of what is known today as 3d printing, but he was unable to file a patent for the technology. It was in 1983 that three unnamed researchers from France sought to revisit the technology, but in a different manner. These researchers sought to use liquid monomers that they would solidify or “cure” with the use of a laser. Both teams are largely credited today as the first to use such technologies; however, they were unable to file their respective patents for the technology.1

Much like the French researchers, one man sought to revisit the technology later that year (1983). Charles W. Hull, while working as the vice-president engineer at Ultra-Violet Products(UVP), a company that used photopolymers to create durable covers for tables, sought to use the resin as a means of rapid prototyping for manufacturers; the only question he had was how. Borrowing his company’s lab during weeknights and weekends, Hull got to work experimenting with how changes in UV light affected the resin. He stayed often after work to continue his experiments.2It wasn’t long before his efforts produced what can be credited as the start of 3d printing—a black-eye wash cup.3 While seeming like such an insignificant part at the time, the cup that Hull had created would lead to the industry we know today.4 Hull was so excited after creating his part, that he called his wife to come down to his lab, still in her pajamas. His wife’s only response was, “This had better be good!”5

Unlike those before him, Hull filed a patent application for his design on August 8, 1984, naming the process “Apparatus for production of three-dimensional products by stereolithography.” The process itself focused a UV light on a vat of UV resin repeatedly to create a specific shape. Hull sought to use 3d printing in order to make use of CAD or Computer-Aided Design software, which generated 3d models in a plane on a computer. Two years later, Hull was granted his patent and co-founded the company 3D Systems, which was at the time the first 3D printing company in the world.6

After founding 3D systems, Hull and his team worked on creating a 3d printer for commercial use, as his original vision for the device was for businesses to create prototypes for their designs quickly and cheaply. In 1987, 3D Systems debuted their creation and the first commercialized 3d printer: the SLA-1 Stereolithography printer. Anyone with the funds could now start creating complicated parts or 3d objects. With Charles Hull as the Chief Technology Officer and the breakthrough machine that is the SLA-1, 3D Systems set out with more products that would change the world.7

While Hull was arguably the most prominent inventor during what is known as the “infant” stage of 3d printing, other inventors were beginning to make their own machines in the decades before the twenty-first century. Carl Deckard and Scott Crump are two inventors whose inventions went overlooked at the time of their invention due to Hull’s success. The SLS or Selective Laser Sintering form of printing, patented by Deckard in 1988, made use of a powder material, instead of Hulls photopolymers, along with a laser, in order to fabricate objects in a similar fashion to 3D Systems’ SLA-1. Crump’s patent filed one year later in 1989, known as FDM or Fused Deposition Modeling (also called Fused Filament Fabrication), is the most popular method of printing by today’s standards, as it made use of melted plastic filament extruded through a nozzle layer-by-layer.8

The next milestone for 3d printing came in 1999 when scientists at Wake Forest Institute for Regenerative Medicine conducted the first transplant of a 3d printed organ. The organ in question was a human bladder, which was first printed by the scientists, then covered by the patient’s own cells, and implanted. Due to the bladder having the cells of the patient that it would be transplanted into, there was no chance of rejection.9

3d printing only expanded from there, beginning with open source software allowing consumers to access CAD software more easily. The expansion of 3d printing into other fields would only grow from there. Dr. Adrian Bowyer, from the University of Bath, made 3d printing even larger when he realized his idea to 3d print a 3d printer, allowing parts and printers to become even more accessible. Technological and Medical uses of 3d printing grew even more throughout the early 2000s, when items such as kidneys, prosthetic limbs, and even the first 3d printed car were printed in 2002, 2008, and 2011, respectively.10

Being the largest company in the industry, 3D Systems experienced immense growth alongside these discoveries. With Hull at the epicenter, 3d printing was recognized as one of the greatest inventions in history. Hull was recognized for his creation by the world and in 2014, was inducted into the National Inventors Hall of Fame.11 Hull’s induction was the introduction of 3d printing to the public eye, inviting numerous companies to create their own lines of printers, and releasing them at affordable prices.

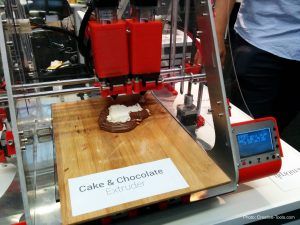

Hull has since been credited as the father of 3d printing, and his success has only grown since. Hull himself did not expect 3d printing to expand in the ways that it did, only seeing the industrial usage of the technology at the time.12 With recent developments such as the first 3d printed building and 3d printed foods, the industry Hull created almost 40 years ago has gone in directions no one would’ve expected.

From its origins in 1981, 3d printing has become one of the most prominent forms of technology for starting a business and has only become more readily accessible for anyone looking to print their designs. Some establishments such as libraries and schools have printers ready to use for either a fee or sometimes for free, depending on the place. 3d printing is now making leaps in the food, medicinal, and construction industries. Printers have been created with enough precision to replicate organs, and large enough to build a house, varying in size and materials. The possibilities of modern 3d printers are limitless, with the only constraints being the user’s imagination.

- “History of 3D Printing: It’s Older Than You Think,” Redshift EN (blog), August 31, 2021, https://redshift.autodesk.com/history-of-3d-printing/. ↵

- Charles W. Hull, “The Birth of 3D Printing: IRI Achievement Award Address: With the Invention of the 3D Printer, Charles Hull Laid the Foundation for Today’s Digital Manufacturing Revolution,” Research-Technology Management (Industrial Research Institute Inc., November 1, 2015),https://www.semanticscholar.org/paper/The-Birth-of-3D-Printing%3A-IRI-Achievement-Award-the-Hull/82a9f235c427cb33b997715c0b5853878e6f7d6c067. ↵

- “Meet Charles Hull, Inventor of Stereolithography,” Fusion 360 (Blog), January 8, 2020, https://www.autodesk.com/products/fusion-360/blog/meet-charles-hull-inventor-of-stereolithography/. ↵

- Reed Miller, “Additive Manufacturing (3D Printing): Past, Present and Future,” Industrial Heating 82, no. 5 (May 2014): 39–43. ↵

- Matthew Ponsford Glass Nick, “‘The Night I Invented 3D Printing’ | CNN Business,” CNN, February 13, 2014, https://www.cnn.com/2014/02/13/tech/innovation/the-night-i-invented-3d-printing-chuck-hall/index.html. ↵

- “Charles Hull,” Ann and H.J. Smead Aerospace Engineering Sciences, September 24, 2018, https://www.colorado.edu/aerospace/charles-hull. ↵

- “Our Story,” 3D Systems, January 12, 2017, https://www.3dsystems.com/our-story. ↵

- “The History of 3D Printing,” MakerBot, March 19, 2019, https://www.makerbot.com/stories/engineering/history-of-3d-printing/. ↵

- “‘A New Bladder Made from My Cells Gave Me My Life Back,’” BBC News, September 10, 2018, sec. Business, https://www.bbc.com/news/business-45470799. ↵

- “Dr. Adrian Bowyer,” https://ultimaker.com, accessed May 11, 2022, https://ultimaker.com/innovators/adrian-bowyer. ↵

- National Inventors Hall of Fame – NIHF, Pioneering 3D Printing: The Chuck Hull Story, 2014, https://www.youtube.com/watch?v=KiVZ8H0hPIk. ↵

- Shane Hickey, “Chuck Hull: The Father of 3D Printing Who Shaped Technology,” The Guardian, June 22, 2014, sec. Business, https://www.theguardian.com/business/2014/jun/22/chuck-hull-father-3d-printing-shaped-technology. ↵

14 comments

Iris Reyna

Wow! Good job on the article Alex. The article was very informative and educational. When I think of 3-D printing I think of the past 2 decades but no it dates back to the ’80s which is really interesting to see how far it’s come and the long history it has. Seeing 3-D printing come from printing prototypes for small things to printing with chocolate and creating 3-D printed organs. Also to read that it was a collaboration of great ideas and wasn’t only just one person that contributed to what 3-D printing is today was fascinating. I can’t even imagine the ideas that people are working on and what will be the next innovation in the coming years.

Ian Poll

3D printing struck me as a fairly recent creation, but now after reading this article it seems that 3D printing, after years of improvements, became a recent popular invention. To me it is almost treated the same way as VR, starts out as a little-known revolution and then spontaneously bursts into mainstream where everyone now has a basic knowledge of its existence. 3D printing is a very useful technology where people can create unique objects without the years of training required if they were to use stock materials.

Kenneth Cruz

Very well written article, Alex! I’ve always been fascinated by the concept of 3-D printing. There is so much good that can come with technology like this. I find it hard to believe that two others before Hull had a similar idea but did not have it patented. If I invented technology like this, I would try to get it patented right away.

Dylan Vargas

I was really brought in by the title and wanted to read and know more about the topic and I’m glad I did. The article gives me a breakdown of one the greatest home style inventions and the story of its evolution. How it started with Hideo Kodama and goes on to be changed by many different people all over the world. It is like a story of the invention and how it became a house held item for people that like to express their creativity or simply just want to make something that helps them in everyday life.

Yanelle Nicholson

This was a very interesting article. I am very surprised how long of a history 3D printing has had. This technology seems like it would be something that was just recently thought of/created, but surprisingly its origins date back to 1981! It is mind-boggling to consider how far 3D printing has come, and it is such a fantastic technological advancement. From the original vision for the device to be for businesses to create prototypes for their designs quickly and cheaply, to now being able to replicate organs.

Guadalupe Altamira

What a great article. The history of 3d was really longer than I thought it would be. I wasn’t expecting it to be created in the 1980s or even if the thought was brought up back then. The details in the article are well written and it was very understanding. It’s very inspiring that Charles Hull was able to work very hard on his creation.

Enrico Zorzin Onzi

Hello Alex, your article is well written, it also contains a lot of detailed and good information about your topic. I did not know that the idea of building a 3d printing started in 1981. As you mentioned, I thought it was a recent technology and still in development. In my opinion, 3d printings are revolutionary, it came to make our lives even easier helping people to develop their designs and boost their business.

Gabriella Parra

Wow! I’m surprised that 3D printing has such a long history. I guess such a innovative concept does need such a large backing of research. It’s amazing to think that Hull worked so hard for a piece of technology that is pretty widespread and accessible today. It makes me wonder, what grand ideas are people tinkering with today that will be mainstream in 40 years?

Kelly Arevalo

Good article! I imagined 3d printing would be something created 14 years ago rather than 40. As you mentioned at the start, this new technology has made possible the rise of new businesses and pathed the way towards a whole new kind of discoveries and scientific evolutions. I am always amazed at the level of preciseness these machines work with and how relatively fast 3d printing has been perfected for medical purposes. Incredible!

Joshua Zemanski

3D printing has always intrigued me, reading this was great and I got to learn way more than I knew before from you. The fact it has a history more than a century old is crazy to me. The fact that he stayed hours after work to learn more about how the UV lights effects the resin just to get a better understanding. Thinking how 3D printing is used now where anyone can really own one of they wanted to, seeing the advancement is unreal. This was a great article Alex, hope to read more of you in the future.